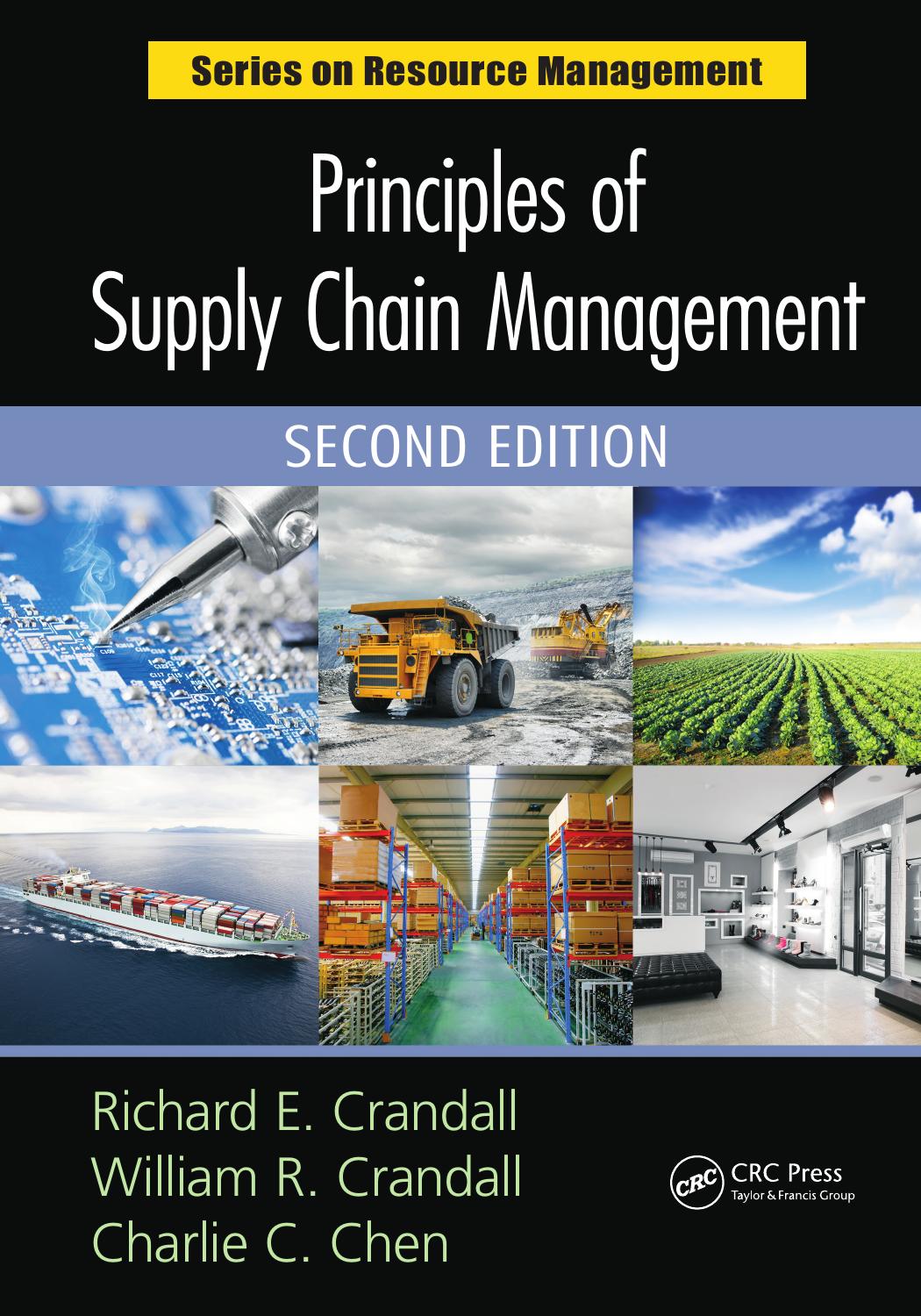

Principles of Supply Chain Management 2nd Edition by Richard Crandall, William Crandall, Charlie Chen ISBN 9781482212068 1482212064

$70.00 Original price was: $70.00.$35.00Current price is: $35.00.

Instant download Principles of Supply Chain Management 2nd Editoin by Richard E. Crandall after payment

Principles of Supply Chain Management 2nd Edition by Richard E. Crandall, William R. Crandall, Charlie C. Chen – Ebook PDF Instant Download/Delivery: 9781482212068 ,1482212064

Full dowload Principles of Supply Chain Management 2nd Edition after payment

Product details:

ISBN 10: 1482212064

ISBN 13: 9781482212068

Author: Richard E. Crandall, William R. Crandall, Charlie C. Chen

The second edition of this popular textbook presents a balanced overview of the principles of supply chain management. Going beyond the usual supply chain text, Principles of Supply Chain Management not only details the individual components of the supply chain, but also illustrates how the pieces must come together. To show the logic behind why su

Principles of Supply Chain Management 2nd EditionTable of contents:

Section I: Overview of Supply Chain Management

TABLE I.1 Principles of Supply Chain Management Overview

Section II: Demand Perspective

Section III: Supply Perspective—Distribution, Production, Procurement, and Logistics

Section IV: Need for Integration

Section V: Financial and Information Technology Perspectives

Section VI: The Future

Section I Overview of Supply Chain Management

1 Evolution of Supply Chains

Learning Outcomes

Company Profile: Procter & Gamble (P&G)

TABLE 1.1 A Comparison of Top 25 Supply Chain Companies: 2008 and 2013

What Is a Supply Chain?

Importance of SCM

FIGURE 1.1 Examples of supply chains for various industries.

Evolution of Supply Chains

Early Supply Chains

Local Supply Chains

Global Supply Chains

Changing Government Orientation

State-Controlled Governments

Market-Driven Governments

Current Trends That Link Supply Chain Participants More Closely

Relationship Building

Customer Relationship Management

Supplier Relationship Management

Product Life Cycle Management

Electronic Business

Developing Economies

Outsourcing

Need for Quality Improvement

Changing Customer Demands

Decreasing Response Time

Lean Supply Chains to Reduce Waste

Current Developments in SCM

Power Has Shifted from Manufacturers to Retailers

Consolidation of Small, Local, or Regional Retailers into National Chains

Emergence of “Killer Category” Retailers

From a Make-and-Sell Mentality to a Sense-and-Respond Orientation

Obstacles to Supply Chain Integration

Need for Globalization

Complexity of Arranging Entities with Common Interests

Lack of Effective Interorganizational Systems

Need for Multiple Supply Chains within Companies

Lack of Trust between Participants

Examples of Companies with Successful Supply Chains

Summary

Hot Topic: Outsourcing to Low Wage Countries

MAKE VERSUS BUY

TOY PROBLEMS

QUESTIONS FOR DISCUSSION

REFERENCES

Discussion Questions

References

2 Supply Chains as a System

Learning Outcomes

Company Profile: Zara’s

Inditex: Zara

INFORMATION GATHERING

PRODUCT DESIGN

MANUFACTURING

DISTRIBUTION

STORES

RESULTS

SYSTEM

REFERENCES

Introduction

FIGURE 2.1 Basic ITO model.

Supply Chain Systems

Inputs

Transformation

Outputs

TABLE 2.1 Examples of ITO Processes in Different Industries

Manufacturing versus Services

Characteristics of Supply Chains

Physical Flow

Information Flow

Funds Flow

Relational Flow

Examples of Supply Chains in Different Industries

TABLE 2.2 Supply Chains for Different Industries

Internal and External Customers

FIGURE 2.2 Role of customers in the ITO model.

Open Systems versus Closed Systems

FIGURE 2.3 Closed versus open systems.

Effect of External Influences on Supply Chains

Obstacles and Enablers of Supply Chain Integration

TABLE 2.3 Potential Impact of External Factors on Supply Chain Systems

Obstacles

TABLE 2.4 Obstacles to Supply Chain Integration for Functional Areas

Enablers

Performance Measurement

Allocation of Costs, Resources, and Benefits along the Supply Chain

TABLE 2.5 Southwest Airlines’ Allocation of Costs, Resources, and Benefits

Value Creation as the Ultimate Objective

Summary

Hot Topic

Hot Topics in the Supply Chain: How a Natural Disaster Can Cripple a Supply Chain

BACKGROUND

FACTORS THAT INTENSIFY THE EFFECT OF A NATURAL DISASTER

Carrying Smaller Inventories

Single Sourcing

Daily Deliveries

Automation

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

References

Section II Demand Perspective

3 Determining Customer Needs

Learning Outcomes

Company Profile: McDonald’s

Company Profile: McDonald’s

BEGINNINGS

GROWTH AND TURMOIL

RECENT CHANGES

REFERENCES

Introduction

Group Customers into Homogeneous Segments

Determine Needs of the Ultimate Consumer

Product Needs

Service Needs

Marketing Mix

Manufacturing and Service Supply Chains

TABLE 3.1 Product and Service Characteristics

Accurately Determine Customer Needs

Approaches

Market Research

Open System Scanning

Competition

Technology

Economy

Government

Social Trends

Business Environment

Develop Reliable Demand Forecasts

Quantitative Forecasting Methods

TABLE 3.2 Summary of Quantitative Forecasting Methods

Simple Moving Average

FIGURE 3.1 Graph of forecast methods.

Weighted Moving Average

Exponential Smoothing

Exponential Smoothing with Trend Adjustment

Seasonal Factor Forecasting

TABLE 3.3 Developing a Seasonal Forecast

Regression Analysis

Qualitative Forecasting Methods

Survey Method

Delphi Method

Collaborative Forecasting

Determine the Attributes of a Well-Designed Product

Functionality (Product Works to Satisfy Customers’ Needs)

Validity (Product Has Value and Functions at a Reasonable Cost)

Manufacturability (Product Can Be Efficiently Produced)

Reliability (Product Has a Variety of Quality Attributes)

Serviceability (Product Can Be Serviced during Its Effective Life)

Recyclability (Product Can Be Recycled along the Reverse Logistics Supply Chain)

Consider Alternative Product Design Approaches

Quality Function Deployment

Concurrent Engineering

Design for Manufacturability

Design for Sustainability

Determine the Number of Supply Chains Needed by a Company

Align with Customer Segment

Align with Product/Service Bundle

Align with Supplier Category

Align with Common Incentives

Respond to Needs of Internal Customers

Conclusion

Hot Topic: Human Trafficking

Hot Topics in the Supply Chain: Is There Human Trafficking in Your Supply Chain?

BACKGROUND

CALIFORNIA TRANSPARENCY IN SUPPLY CHAINS ACT OF 2010

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

References

4 A System to Meet Customer Needs

Learning Outcomes

Company Profile: GE Aviation

Company Profile: General Electric

CUSTOMER RELATIONSHIP MANAGEMENT

PRODUCT LIFE CYCLE MANAGEMENT

OTHER PROGRAMS

REFERENCES

Supply Chain Models

FIGURE 4.1 SCOR model scope and structure.

TABLE 4.1 Supply Chain Activities of Five SCOR Processes

Global Supply Chain Forum Model

TABLE 4.2 Differences between SCOR and GSCF

Customer Relationship Management

Origins of CRM

What Can CRM Do?

Benefits

CRM Processes

Problems

CRM’s Future

Product Life Cycle Management

What Is PLM?

How Did PLM Evolve?

What Does PLM Include?

What Does PLM Not Include?

What Are the Benefits of PLM?

What Are the Obstacles?

What Is the Present Status of PLM?

What Does the Future Hold?

Supply Chain Configuration

Basic (Generic) Supply Chain

Variations for Different Industries

Supply Chain Mapping

Determining Resource Requirements

Facilities

FIGURE 4.2 Examples of different supply chains.

FIGURE 4.3 Supply chain map for apparel.

FIGURE 4.4 Mapping a reverse supply chain network.

TABLE 4.3 Facility Location Strategies and Their Characteristics

Equipment

Employees

Inventory

Information Systems

Designing Processes to Match with Products

FIGURE 4.5 Product–process matrix.

Make to Stock

Assemble to Order

Make to Order

Engineer to Order

Determining the Mix of Make and Buy

Core Competency Concept

Total Cost of Ownership

Cost Reduction versus Revenue Increase Considerations

Effect of Outsourcing Movement

Aligning Entities along the Supply Chain

Entities to Be Involved

Allocation of Authority and Responsibility among Entities

Collaboration Process

Implementation Plan

Evaluating the System Design

Will It Accomplish Its Objectives?

Is It Sustainable?

Is It Flexible?

Summary

Hot Topic: Sweatshops

Hot Topics in the Supply Chain: Sweatshops—Two Sides of the Same Coin

BACKGROUND

CRITICS OF SWEATSHOPS

SUPPORTERS OF SWEATSHOPS

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

References

5 Demand Management

Learning Outcomes

Company Profile: NextEra

Company Profile: NextEra

SOURCES OF DEMAND AND SUPPLY

EVOLUTION

DEMAND MANAGEMENT STRATEGIES

OBSTACLES

SUSTAINABILITY

REFERENCES

Introduction

Definition of Demand Management

FIGURE 5.1 Traditional approach to demand management.

FIGURE 5.2 Contemporary approach to demand management.

Importance of Demand Management

Managing Demand

Accept All Demand

Select the Types of Demand to Accept

Solicit External Input in Forming Demand Patterns

Design the Form in Which Demand Will Be Accepted

Impose Constraints on Demand Submission

Managing Supply

Select a Demand Management Strategy

Develop a Demand-Forecasting System

Determine the Resource Requirements to Meet the Demand

Merging Supply and Demand into a Demand Management Process

Sales and Operations Planning to Match Short-Term Supply and Demand

Collaboration among Supply Chain Participants

Demand Management in Manufacturing

Demand Management in Services

Proposed Demand Management Strategies

FIGURE 5.3 Demand management strategies.

Factors That Affect Selection of a Demand Management Strategy

Resources’ Value

TABLE 5.1 Factors That Influence Demand Management Strategies

TABLE 5.2 Demand Management Strategies and Resource Factors

TABLE 5.3 Demand Management Strategies and Demand Factors

Type of Demand

Top Management Strategies

TABLE 5.4 Demand Management Strategies and Strategic Factors

Relationship between Factors and Strategies

TABLE 5.5 Two Examples of Factors That Influence Demand Management Strategies

Model for Integrating Demand and Supply Management

TABLE 5.6 Comparison of Marketing and Operations Demand Management Strategies

FIGURE 5.4 Integrated demand management planning model.

TABLE 5.7 Planning Example for Marketing and Operations

Programs Used to Implement Demand Management Strategies

Provide Strategy Programs

TABLE 5.8 Demand Management Programs

Match Strategy Programs

Influence Strategy Programs

Control Strategy Programs

Demand Management along the Supply Chain

Retail

Wholesale

Manufacturer

Mining and Agriculture

Summary

Hot Topics in the Supply Chain: The Problem of Cheap

GRESHAM’s LAW AND DISCOUNT GOODS

WHERE HAVE ALL THE GOOD PRODUCTS GONE?

LINK TO INNOVATION

Questions for Research and Discussion

References

Discussion Questions

References

Section III Supply Perspective—Distribution, Production, Procurement, and Logistics

6 Distribution and Retailing

Learning Outcomes

Company Profile: Lowe’s

Company Profile: Lowe’s

RETAIL

DISTRIBUTION

SUSTAINABILITY AND SOCIAL RESPONSIBILITY

References

Introduction

Retail Function

History of Retailing

FIGURE 6.1 Evolution of retail stores.

TABLE 6.1 Major Types of Retail Stores

TABLE 6.2 Types of Nonstore Retailers

Characteristics of the Industry

Customers and Markets

TABLE 6.3 Relative Size of Major Industries in the United States

Outputs

Inputs

Transformation Process

FIGURE 6.2 The four P’s of marketing.

Impact on Operations Management

Designing the Retail Process

Strategic Orientation

Critical Design Points: Keys to Success

TABLE 6.4 Levels of Personal Contact

TABLE 6.5 Considerations in Retail Store Layouts

Additional Factors to Consider in Retail Store Design

Multidiscipline Project

Continuing Need to Readjust or Redesign

E-Commerce Considerations (Direct vs. Indirect Selling)

Strategic or Long-Term Considerations

Managing a Retail Business

Determine the Expected Demand

Plan Capacity to Meet Demand

Implement the Operating Plan

Measure Performance

Replan for the Next Period

Retail and Inventory Management

Value

Availability

Variety

Presentation

Service

Response Time

Present Situation in Retailing

Future in Retailing

Role of Wholesalers and Distribution Centers

Ordering

Receiving

Stocking

Picking

Loading the Trucks

Transporting to Stores

Unloading and Display at Stores

Critical Success Factors for Distribution

Inventory within Distribution Functions

Inventory Management between Retailer and Distributor

Technology in Distribution Functions

At the Retail Store

Movement of Goods

At the Distribution Center

Distribution Center Design

Positioning Services within the Distribution Functions

Presale Services

Postsale Services

Role of Third-Party Service Providers

Distribution Performance Measurement

Financial Performance Measures

Operating Performance Measures

Collaboration Performance Measures

Retailer–Distributor Relationship

Summary

Hot Topic: Contaminated Milk

Hot Topics in the Supply Chain: The Problem of the Middleman and a Milk Crisis in China

BACKGROUND

FIGURE 6.3 The supply chain for melamine-laced milk.

COMPANY RESPONSE

Questions for Research and Discussion

References

Discussion Questions

References

7 Production and Service Processes

Learning Outcomes

Company Profile: Caterpillar

Company Profile: Caterpillar Inc.

LINES OF BUSINESS

PROCESSES

TABLE 7.1 Business Segments with Sales and Profits by Segment

SERVICES

LOCATIONS

TABLE 7.2 Manufacturing Locations throughout the World

TABLE 7.3 Manufacturing Locations outside the United States

EMPLOYEES

RESEARCH AND DEVELOPMENT

SUSTAINABILITY

STRATEGY DURING THE RECENT ECONOMIC DOWNTURN

REFERENCES

Introduction

FIGURE 7.1 Basic input–transformation–output (ITO) model.

FIGURE 7.2 Evolution of the expanded supply chain. As companies extend their supply chain, both forward to the customers and back to the suppliers complexity increases, making communications more critical; variability in demand decreases, making reduced inventories possible; interdependence increases, making delivery reliability more important; supplier dependability increases, making fewer suppliers necessary; and material flow smooths, making lead (response) times shorter.

Evolution of the Production Function

From Craft to Mass Production

From Mass Production to Mass Customization

FIGURE 7.3 From the craft age to the mass customization age.

Critical Success Factors for Manufacturers

Cost and Efficiency

Quality

Responsiveness: Timing of Delivery

Responsiveness: Product/Service Mix

Flexibility

Agility

Information Technology

Manufacturing Strategies

FIGURE 7.4 Traditional production.

Make to Stock

Locate to Order

Assemble to Order

Make to Order

Engineer to Order

Batch to Lean Operations

Present Batch Flow

FIGURE 7.5 Review of batch flow characteristics.

FIGURE 7.6 Physical layout—a process layout.

Machine Breakdowns

Supplier Failures

Worker Flexibility

Customer Lead Times

Customer Order Size

Proposed Lean Production Flow

Customer Lead Time

FIGURE 7.7 Review of JIT characteristics.

FIGURE 7.8 Physical layout—with manufacturing cells.

Extra Available Space

Faster Detection of Quality Problems

Ease of Transferring Operators

Reduced Scheduling Requirements

Smaller Lot Sizes

No Buildup of WIP Inventory

Empowered Employees

Reduced Equipment Breakdowns

Reduced Late Material Deliveries

Reduced Write-Off of Inventory

Obstacles to Implementing Lean

Make or Buy Strategies

Vertical Integration

Outsourcing

TABLE 7.4 Total Cost of Ownership Model

Capacity Planning

How Much Capacity? When? What Kind?

Location and Ownership

Service Production Strategies

Relationships with Downstream Customers

FIGURE 7.9 Product–process matrix.

From Transactions to Processes

Transactions versus Processes

Basic Processes of a Business

Benefits of a Process Orientation

Effect of Process Orientation

Organizational Structure

Strategies

Knowledge Management

Change Management

Trends in Production

From Manual to Automated

From Domestic to Global

From Standard Products to Customized

Postponement

Sales and Operations Planning

Additive Manufacturing

Performance Measurement

As Measured by Accounting

As Measured by Production

Measures along the Supply Chain

Summary

Hot Topic: Clothing Manufacturing

Hot Topics in the Supply Chain: Clothing, the Achilles Heel of the Supply Chain

CODES OF CONDUCT

ROLE OF THE HOST GOVERNMENT

QUESTIONS FOR RESEARCH AND DISCUSSION

References

Discussion Questions

References

8 Procurement/Purchasing

Learning Outcomes

Company Profile: Nestlé

Company Profile: Nestlé

PRODUCTS AND MARKETS

VALUE STATEMENTS

TABLE 8.1 Nestlé Sales for 2012

TABLE 8.2 Nestlé Employees and Factories

PURCHASING

Palm Oil

Soya

Paper and Paperboard

Water

SUSTAINABILITY

CONCLUSION

REFERENCES

Introduction

FIGURE 8.1 Purchasing along a clothing manufacturer supply chain.

Role of Procurement in the Supply Chain

Traditional Purchasing

TABLE 8.3 Vendor Rating System

Contemporary Purchasing

Changing Role of Purchasing

TABLE 8.4 Stages of Purchasing Sophistication

Critical Success Factors for Purchasing

Functionality

Availability

Cost

Quality

Match Inflow with Outflow

Reduce Variances in Delivery

Increase Supplier Dependability

Reduce the Bullwhip Effect

Become an Intercompany Facilitator

Find Sustainable Suppliers

Purchasing Functions: Participating

Product Design

Product Specifications

New Product Introduction

MANAGERIAL COMMENT 8.1 ROLE OF PURCHASING IN NEW PRODUCT INTRODUCTION

MATERIALS MANAGEMENT

WHERE SPRINT CAN ADD VALUE

TABLE 8.5 Steps in the SPRINT Project

Target Costing

Strategic Sourcing

Supplier Location

Inventory Management

Supplier Risk Management

Purchasing Functions: Directing

Purchasing Process

FIGURE 8.2 Purchase order process flow. 1, Prepare order and send to supplier; 2, supplier checks credit of customer before shipping; 3, supplier prepares order for shipment; 4, supplier prepares invoice; 5, supplier ships to customer, directly or through third party; 6, purchasing sends purchase order to accounting; 7, operations sends receiving report to accounting; 8, supplier sends invoice to customer (accounts payable); 9, accounts payable reconciles purchase order, receiving report and invoice; approves payment; 10, customer bank sends electronic funds transfer to supplier bank.

Supplier Evaluation

Supplier Relationship Management

Supply Chain Coordination/Collaboration

Purchasing along the Supply Chain

Consumer

Retail

Wholesale

Manufacturer

Mining and Agriculture

Services

Offshore Outsourcing

As a Strategic Concept

TCO Considerations

TABLE 8.6 Stages of Purchasing Sophistication

As a Project, with Project Management Needs

Other Considerations: Intangible Costs and Public Acceptance

Supplier Location as a Strategy for Entering an Offshore Market

Performance Measurement

Traditional: Positive Purchase Price Variance

Contemporary: Enhanced Value for the Consumer

Future of Purchasing

Summary

Hot Topic: Apple Juice

Hot Topics in the Supply Chain: Why Apple Juice Should Be Made from… Apples

BACKGROUND

THE AFTERMATH

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

References

9 Logistics: The Glue That Holds the Supply Chain Together

Learning Outcomes

Company Profile: Transportation Insight

Company Profile: Transportation Insight

HISTORY

About 3PLs

TRANSPORTATION INSIGHT SERVICES

SUCCESS STORIES

FIGURE 9.1 Supply chain analytics.

BENEFITS

CONCLUSIONS

REFERENCES

Scope of Logistics

Evolution of Integrated Logistics

FIGURE 9.2 Integrated logistics in a supply chain.

FIGURE 9.3 Evolution of the supply chain.

FIGURE 9.4 Evolution of integrated logistics.

Transportation

Truck: Privately Owned or Third-Party Carriers

Rail: For Selected Goods

Waterways

Air

Pipeline

Parcel

Transmission Lines

Fiber-Optic Cable Networks

Materials Management

Interim Storage

Exchange Points

Traceability

Integration

Outsourcing

Drivers of the Outsourcing Movement

Sustainability

Social Responsibility

Ethical Responsibility

Future Company Well-Being

Steps in the Outsourcing Decision

Step 1. Determine Project Feasibility

FIGURE 9.5 An approach to outsourcing decision making.

Step 2. Prepare a Project Plan

Step 3. Estimate Annual Savings

Step 4. Identify Risks or Disruption Costs

Step 5. Estimate the Return on Invested Capital

Step 6. Implement the Offshore Outsourcing Program

Step 7. Measure Progress

Step 8. Review and Revise

Summary

Reshoring Initiative

Rise of 3PLs

TABLE 9.1 Global 3PL Market Size Estimates

FIGURE 9.6 Origins of 3PLs.

FIGURE 9.7 Classification of 3PLs.

Benefits of 3PL Services

Reduces Total Cost

Decreases Total Time from Origin to Destination

Results in More Consistent Processing: Less Variability in Elapsed Time

Allows Individual Participants to Concentrate on Core Functions

Increases Flexibility of the Supply Chain

Leads to Market Development through 3PL Contacts

Taps into Specialized Knowledge Not Normally Internal to Company

Obstacles to Successful Implementation

Lack of Qualified Personnel within the Company to Manage the 3PLs

Lack of Full-Service Providers

Perceived Loss of Control by Outsourcing Company

Difficulty in Coordinating Disparate Participants

Lack of a Comprehensive Financial Analysis before Implementing

Difficulty in Selecting and Using Appropriate Performance Measures

Trend toward Outsourcing the Distribution Function

Major Companies

Role of 4PL in Building Supply Chain Relationships

High-Tech Industry Issues

TABLE 9.2 Priorities of High-Tech Supply Chains

Risk Management

Status Report

TABLE 9.3 Shipper and 3PL Challenges

Hot Topic

Hot Topics in the Supply Chain: Container Shipping and its Risk Points

CONTAINER SHIPPING AND ITS RISKS

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

References

10 Reverse Supply Chains

Learning Outcomes

Company Profile: GENCO

Company Profile: Reverse Logistics GENCO

COMPANY HISTORY

DISCUSSION OF REVERSE LOGISTICS

DESCRIPTION OF REVERSE LOGISTICS AT GENCO

TABLE 10.1 Returns Management Services at GENCO

DESCRIPTION OF PLM AT GENCO

REFERENCES

Introduction

Description of Reverse Supply Chain Networks

Benefits of Reverse Logistics*

Barriers to Reverse Logistics

Continuation of Forward Supply Chains

FIGURE 10.1 Forward (downstream) supply chain.

FIGURE 10.2 Product life cycles.

History of Reverse Logistics

Principal Drivers of the Movement

Individual Consumers

MANAGERIAL COMMENT 10.1 EVOLUTION OF REVERSE LOGISTICS

Individual Businesses

Society as a Group

Environmental Concerns

Resource Scarcity Concerns

Business Sector

Economic Benefits Possible

New Businesses, Even New Industries, Possible

Educational Institutions

Governments: At All Levels

Activities in Reverse Logistics

Service: Assure Proper Use of Product

Returns: Repackaging or Relocation

Restoration: Minor Modification or Repair

Remanufacturing: Overhaul and Major Rebuilding

Recycling: Reconstitution as Part of Another Product

Disposal: Return to Natural State

Hazardous Waste Disposal

Role of Private Industry

New Paradigms in Product Design (Design for Sustainability)

Design and Operate Green Supply Chains

Develop Systems to Manage Reverse Logistics

Participate in Joint Ventures to Seek Social Objectives

Role of Government

Research: To Identify Threats and Opportunities

Legislation: To Standardize Business Requirements

Regulation: To Monitor Performance

Participation: To Encourage and Support Ongoing Programs

Role of Consumer

Participant in Reverse Supply Chain Programs

Educated Consumer

Supporter of Green Supply Chain Efforts

Reverse Logistics Network

Continuation of the Forward Supply Chain

Open System Environment

Heavily Outsourced by Major Businesses

Need for a Life Cycle Systems Approach*

FIGURE 10.3 Excess inventory life cycle model.

FIGURE 10.4 Factors to consider during RSC life cycles.

Need for IT

Other Considerations in Designing Reverse Supply Chains

Future

Growth in Amount of Materials Recycled

Increase in Number of Companies Performing Reverse Logistics Activities

Joint Ventures between Private Business and Government

Increased Emphasis on Prevention, Not Just Reusing

More Companies Will Design Integrated Reverse Logistics Systems

Summary

Hot Topics in the Supply Chain, Reshoring: Revisiting the Make or Buy Decision

REASONS FOR RESHORING

THE BIG PICTURE

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

References

Section IV Need for Integration

11 The Need to Integrate

Expected Outcomes

Company Profile: Cisco

Company Profile: Cisco

HISTORY OF COMPANY

FIGURE 11.1 Cisco sales.

MARKETS

PRODUCTS

TABLE 11.1 Cisco Markets

TABLE 11.2 2012 Net Sales by Product Groups

SUPPLY CHAIN STRUCTURE

RISK MANAGEMENT

CONCLUSION

REFERENCES

Introduction*

Setting the Stage *

Reasons to Integrate

Research in Support of Integration Efforts

From Mass Production to Mass Customization

From Craft to Mass Production

Prelude to Mass Customization

TABLE 11.3 Examples of Movement toward Mass Customization

From Vertical Integration to Virtual Integration

From Homogeneous Cultures to Diverse Cultures

From Bottom Line to Triple Bottom Line

Drivers of Change

Global Competition

Global Markets

Economic Advantage

Lower Costs

Higher Revenues

Relationships and Trust among Supply Chain Participants

Trust between Individuals

Formal Contracts or Agreements

Common Interests or Projects (Enforced Trust)

Involves Change Management

Change Is Difficult within a Company

Embedded Culture

Policies and Procedures

Organization Structure

Customer Relationships

Supplier Relationships

Union Relationships

Change Is More Difficult for a Community

Company–Community Relationship

Difficulty in Changing Laws and Regulations

Difficulty in Changing Infrastructure

Change Is Most Difficult for an Entire Country

Political Implications

Regional Differences

Steps in the Integration Process

Build Interfaces with Customers and Suppliers

Change Interfaces to Interlaces to Make the Relationships Closer

Change Interlaces to Integrated Relationships

Need for Strategic Planning

Categories of Operations

Normal Operations

Improvement Programs

Problem-Solving Programs

Crisis Management

Need for a Multiyear Project Plan

Performance Measurement across the Supply Chain

Integration Requires Sharing

Summary

Hot Topic: AECL, Part 1

Hot Topics in the Supply Chain: Atomic Energy Canada Limited Encounters Problems with Its Cancer-Fighting Machine, Part 1

BACKGROUND

FIGURE 11.2 Information asymmetry along the supply chain.

PROBLEM OF INFORMATION ASYMMETRY

QUESTIONS FOR DISCUSSION

REFERENCES

Discussion Questions

References

12 Why Integration Is Difficult

Learning Outcomes

Company Profile: Boeing

Company Profile: Boeing

INTRODUCTION

HISTORY

TABLE 12.1 Boeing Aircraft over the Years

TABLE 12.2 Revenues and Earnings by Business Segment

TABLE 12.3 Number of Airplanes Delivered by Model

DESCRIPTION OF DREAMLINER

DESCRIPTION OF 787 SUPPLY CHAIN

DIFFICULTIES

OUTLOOK

CONCLUSIONS

REFERENCES

Introduction

Determining Strategic Objectives

Evaluating the Potential Return on Investment

Uncertainty of Benefits

Tangible or Direct

Intangible or Indirect

Uncertainty of Costs

Product Costs

Support (Overhead) Costs

Uncertainty of Assets Employed

Designing for Participant Differences

Participants Are Not Equal

Commitment

Contribution

Different Roles: Drivers and Followers

Technical Differences

Size

Proximity

Type of Operation

Need for Multiple Supply Chains

Different Customer Segments

Different Supplier Segments

FIGURE 12.1 Examples of inventory locations in different supply chain strategies.

FIGURE 12.2 Multiple supply chains for Manufacturer 1.

Different Logistics Networks

Separating Interwoven Networks

Selecting and Implementing Technology

Product and Service Processes

Remove Barriers

Eliminate Redundancy

Develop Compatible Processes

Strive for Effectiveness and Efficiency

Incomplete Interorganizational Systems

Lack of Systems Compatibility

Lack of Information

Lack of a System

Financial Funds Flow

Realigning Infrastructure

Internal Organization

Effect of Outsourcing Movement

External Organization

Policies and Procedures

Physical Infrastructure

Transforming Company Cultures

Internal

External

Building Relationships

Communicate

Coordinate

Cooperate

Collaborate*

Lack of Trust Inhibits Collaboration

Measuring Performance

Maintaining the System

During the Implementation Process

During the Operation of the Supply Chain

Extension into Reverse Logistics

Obstacles to International SCM

Summary

Hot Topics in the Supply Chain: Atomic Energy Canada Limited Encounters Problems with Its Cancer Fighting Machine (Part 2)

BACKGROUND

POTENTIAL OBSTACLES TO INTEGRATION

TABLE 12.4 Overview of the Accidents

Questions for Discussion

REFERENCES

Discussion Questions

References

13 How to Build an Integrated Supply Chain

Learning Outcomes

Company Profile: Interface, Inc.

INTRODUCTION

HISTORY

PRODUCTS

GLOBAL MARKETS

TABLE 13.1 2012 Sales and Assets Deployed (Millions of Dollars)

SUPPLY CHAIN

REVERSE SUPPLY CHAIN

SUSTAINABILITY

COOL CARPET™

CONCLUSIONS

REFERENCES

Introduction

Who Manages the Supply Chain?*

Past and Future of Supply Chain Management

FIGURE 13.1 Tightly linked or controlled supply chain under one major participant.

FIGURE 13.2 Loosely coupled supply chain with aligned direction through collaborative links throughout.

Present Supply Chains

FIGURE 13.3 Loosely linked supply chains without direct route to ultimate consumer.

Virtual Supply Chains

Contractual Alliances

Dominant Party Management

Third-Party Direct Management

Third-Party Indirect (Third-Party) Management

World of Lean Production*

Product

Purchasing Process

Production Process

Delivery Process

Demand Variation

Moving from Functional Focus to Cross-Enterprise Collaboration

Comprehensive Supply Chain Model

FIGURE 13.4 Transition to an integrated supply chain.

Decisions Needed to Achieve a Lean and Agile Supply Chain

Commitment

Concept

Configuration

Top Management

Marketing

TABLE 13.2 Supply Chain Basics for Top Management

TABLE 13.3 Supply Chain Basics for Marketing

Purchasing

TABLE 13.4 Supply Chain Basics for Purchasing

Manufacturing

Distribution

Finance and Accounting

TABLE 13.5 Supply Chain Basics for Manufacturing

TABLE 13.6 Supply Chain Basics for the Distribution Function

TABLE 13.7 Supply Chain Basics for the Finance and Accounting Functions

Communication

Culture

Customization

Integrated Supply Chain

Coordination

Cooperation

Collaboration

MANAGERIAL COMMENT 13.1 BEATING IMPOSSIBLE DEADLINES

PROGRAMS

Quick Response Systems

Continuous Replenishment Programs

Efficient Consumer Response

Vendor-Managed Inventory

Collaborative Planning, Forecasting, and Replenishment

PRESENT STATUS

FUTURE

MANAGERIAL COMMENT 13.2 TRUST

Steps in the Change Process

Investigate

Involve

Include

Initiate

Invigorate

Implement

Integrate

Institutionalize

Innovate

A Look Ahead

Complexity

Clairvoyance

MANAGERIAL COMMENT 13.3 Implications for the Left Hemisphere

LEFT-BRAIN THINKING

Summary

Hot Topics in the Supply Chain: Atomic Energy Canada Limited Encounters Problems with its Cancer-Fighting Machine (Part 3)

SUPPLY CHAIN DURING A CRISIS

INVESTIGATING THE CAUSE OF THE ACCIDENTS

REALITY OF SOFTWARE BUGS

CONCLUSION

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

References

Section V Financial and Information Technology Perspectives

14 Information Flow along the Supply Chain

Learning Outcomes

Company Profile

Company Profile: SAP

INTRODUCTION

HISTORY

TABLE 14.1 Key Milestones in the History of SAP AG

PRODUCTS AND SERVICES

TABLE 14.2 Total Revenue by Region (in Millions of Euros)

Applications

Analytics

Cloud

Mobile

Database and Technology

SOLUTIONS FOR LINES OF BUSINESS

SOLUTIONS FOR INDUSTRIES

TABLE 14.3 Revenue by Industry Group

SUPPLY CHAIN INFORMATION

EXTERNAL APPLICATIONS

CONCLUSIONS

TABLE 14.4 SAP Sustainability Measures for the Past 5 Years

REFERENCES

Introduction

Need for Information Flow

FIGURE 14.1 Input–transformation–output–customer (ITOC) model.

Types of Information Transmitted

Upstream Suppliers

Midstream (Internal)

Downstream Customers

Reverse Supply Chain

Supply Chain Connectivity

FIGURE 14.2 Supply chain ITs.

Intracompany Technologies Used

Data Capture and Communication

Computer-Aided Design

Point-of-Sale Terminals

Automatic Identification Systems

Groupware

Data Storage and Retrieval

Data Manipulation and Reporting

Supply Chain Direct Links

Customer Relationship Management

Supplier Relationship Management

Linking Technologies

Interorganizational Systems

EDI and Internet EDI

Linking Applications

Videoconferencing

Sales and Operations Planning

Product Life Cycle Management

Third-Party Services

Service-Oriented Architecture

Software as a Service

Cloud Computing

Benefits of Information Technologies

Tangible Benefits

Increase Revenues

Reduce Product Costs

Reduce Transaction Costs

Reduce Product Development Lead Time

Reduce Capital Investment Costs

Intangible Benefits

Improve Customer Relations

Improve Decision Making

Streamline Administrative Processes

Integrate Company Planning and Execution

Barriers to IT Adoption

Technological Obstacles

Standards Interoperability

Back-End Interoperability

Scope of Applications

Security

Managerial Obstacles

Power Structure

Trust

Economic Issues

Employee Acceptance

Societal Obstacles

Model of an Integrated Supply Chain Information System

FIGURE 14.3 An integrated supply chain information system model.

Summary

Hot Topic

Hot Topics—The Boeing 787: A New Supply Chain Model in the Commercial Aircraft Industry—Part 1

HOW THE BOEING 787 SUPPLY CHAIN IS DIFFERENT

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

References

15 Funds Flow along the Supply Chain

Learning Outcomes

Company Profile: Wells Fargo

Company Profile: Wells Fargo

INTRODUCTION

BENEFITS OF IMPROVED FUNDS FLOW

WAYS TO IMPROVE

SUPPLY CHAIN FINANCE

SUPPLY CHAIN FINANCE AT WELLS FARGO

SUMMARY

REFERENCES

Overview of the Flow of Funds

FIGURE 15.1 Supply chain flows—products, information, and funds.

Need for Cash Flow within a Company

Supply Chain Funds Flow*

Flows in a Supply Chain

Benefits of Improved Funds Flow

Obstacles

External Sources of Funds

Banks and Other Lending Institutions

Supply Chain Finance

Performance Measurement

Financial Accounting Measures: Current Ratio

Management Accounting Measures

FIGURE 15.2 Cash flow cycles.

Need for Finance and Operations to Collaborate

Effect of Production Strategies on Funds Flow

FIGURE 15.3 Effect of production strategies on inventory.

Effect of Outsourcing on Product Costs and Capital Requirements

Interorganizational Systems*

Benefits

Obstacles

Evolution

Future

EDI*

Benefits

Funds Flow in the Reverse Supply Chain

Comprehensive Example*

Components of a Financial Statement

Analyzing the Cash Flow Statement

FIGURE 15.4 Cash flow links between income statement and changes in balance sheets.

Looking at Alternatives

TABLE 15.1 Net Work Capital Forecasts

TABLE 15.2 Actions to Improve Working Capital Management

Summary

Hot Topic: Boeing 787 Dreamliner

Hot Topics in the Supply Chain: The Boeing 787, Problems in the Supply Chain (Part 2)

PROBLEMS IN THE SUPPLY CHAIN

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

REFERENCES

16 ROI for Supply Chains and Other Issues

Learning Outcomes

Company Profile: Apple

Company Profile: Apple

INTRODUCTION

TABLE 16.1 Views of Supply Chains from Jobs and Cook

APPLE’s RANKING AS A SUPPLY CHAIN COMPANY

SUPPORTING EVIDENCE

TABLE 16.2 Apple Management Performance Measures

SEGMENT SALES

TABLE 16.3 Sales by Market Area

TABLE 16.4 Sales by Product Segment

WHY APPLE MUST MANAGE THEIR SUPPLY CHAINS

OBSTACLES OR PROBLEMS

CONCLUSIONS

REFERENCES

Supply Chain Configurations

FIGURE 16.1 Loosely linked supply chains without direct route to ultimate consumer.

Programs Requiring Close Supply Chain Relationships*

Need to Evaluate Supply Chain ROI

Tangible Benefits

Reduced Inventory

Reduced Cycle Times

Improved Customer Service

Improved Quality

Tangible Costs

Communications

Retraining Internal Employees

Restructure Supplier Network

Design Customer Network

Capital Investment

Indirect Costs

Meetings Required to Organize Customer and Supplier Relationships

Programs to Change Internal Culture

Changes in Organization Structure

Realignment of Roles of Supply Chain Participants

Intangible Benefits

Integrated Flow of Goods and Services

Faster Resolution of Problems

Match Customer Wants with Products Provided

Reduced Excess Capacity along the Supply Chain

Increased Knowledge

Reduced Risk of Supply Chain Disruption

Intangible Costs

Loss of Confidential Information

Increased Awareness of Inequitable Treatment among Participants

Discrepancy between Contribution and Payoff among Participants

Legal Actions

Obstacles to Equitable Distribution among Members

How to Organize?

How to Distribute?

Supply Chain Governance Models

TABLE 16.5 Supply Chain Governance Categories

Prime Mover in the Supply Chain

Organize

Select the Team

Monitor Ongoing Operations

Evaluate Performance

Initiate Change

Third-Party Provider

Changes in Supply Chain Composition

Dictated by Prime Mover

Consensus of the Supply Chain Participants

Consultation with an Outside Adviser

Mediation by Third Party

Legal Action

Case Studies

Use of Accounting Records

RFID Implementation

Cost Reductions with Investment Requirements

Supply Chain Finance

Benefits of Supply Chain Collaboration

Summary

Hot Topic

Hot Topics in the Supply Chain: The Boeing 787, Pushing the Limits of Outsourcing (Part 3)

LOSS OF INTELLECTUAL CAPITAL

FORMER SUPPLIERS MAY BECOME COMPETITORS

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

REFERENCES

Section VI The Future

17 Trends in Supply Chain Management

Learning Outcomes

Company Profile: Amazon

Company Profile: Amazon.com

OVERVIEW

TABLE 17.1 Amazon Sales, Income, and Cash Flow for 2007–2013

TABLE 17.2 Operating Expenses by Type for 2009–2013

RETAILING: PRODUCTS AND SERVICES

DISTRIBUTION (FULFILLMENT CENTERS)

MANUFACTURING (KINDLE)

ORIGINATION (BOOK AUTHORS)

SERVICES

SUMMARY

REFERENCES

From the Past to the Present

From the American Revolution to World War II

From World War II until the Present

Evolution of Critical Success Factors in the United States*

TABLE 17.3 Evolution of CSFs in the United States

Beginning (from First Settlements through 1800)

Industrial Revolution (1840s–1890s)

Growth and Recovery (1890s–1930s)

Mass Production (1940s–1950s)

Arisings (1960s–1970s)

Awakening (1980s)

Globalization I (1990s)

Globalization II and Mass Customization (2000 and after)

Major Drivers of Change in Supply Chains

Global Business Perspective

Balanced Approach to Offshore Outsourcing

Total Cost of Ownership

Risk Management

Other Issues

Continuing Advances in Technology

Retail Operations

Demand Forecasting

Transportation and Distribution

Information Systems

From Special-Purpose to General-Purpose Resources

Evolution from Transactions to Processes*

Transactions versus Processes

Benefits of a Process Orientation

Vanishing Boundaries between Manufacturing and Services

Infrastructure Refinements

From Vertical to Horizontal Organizations*

From Rigid Rules to Flexible Policies and Procedures

From Tacit Knowledge to Implicit Knowledge

From Financial Accounting to Management Accounting

Culture and Employees

From Passive or Obstructing Culture to Engaged and Receptive Culture

Employees: From Specialized to Empowered

TABLE 17.4 Changes in the Nature of Manufacturing Tasks

TABLE 17.5 Changes in Required Skills for Manufacturing Personnel

Supply Chain Relationships

From Adversarial to Collaborative

Trust and Distrust

TABLE 17.6 Trust versus Distrust

Emergence of Third-Party Supply Chain Coordinators

Risk Management*

Increased Complexity and Risk

TABLE 17.7 Comparison of Risk Management Paradigms

FIGURE 17.1 Risk frequency versus severity.

Internal Risks

External (Open System Environment) Influences

Natural Disasters

TABLE 17.8 Number of Major Disasters

Sustainability*

Triple Bottom Line

Beyond the Triple Bottom Line

Why Should Business Take the Lead?

Need for Alliances

Benefits and Obstacles

Sustainability in the Future

Strategic Employee Plan

Summary

Hot Topic

Hot Topics in the Supply Chain: Finding Solutions to the Sweatshop Problem

Background

Recommendations

MNCs Will Need to Take a Long-Term View toward Their Suppliers

MNCs Will Need to Commit Resources to Improve Their First-Tier Suppliers in Developing Countries

QUESTIONS FOR RESEARCH AND DISCUSSION

REFERENCES

Discussion Questions

References

18 Preparation for the Future

Learning Outcomes

Company Profile

Company Profile: Google

REVENUE

TABLE 18.1 Comparison of Big Tech Companies at Age 15

FINANCIAL RESULTS

MAJOR BUSINESS SEGMENTS (FROM THE 2012 10-K REPORT)

Google Search

Advertising

TABLE 18.2 Google Income and Cash Flow Results (2009–2013)

Operating Systems and Platforms

TABLE 18.3 Comparison of Key Financial Results for Google (2009–2013)

Enterprise

Motorola

SWOT ANALYSIS

GOOGLE LOCATIONS

OTHER INTERESTS

Google Glass

Driverless Car

SUMMARY

References

Recognize the Need to Adapt

Globalization

Competition

Economy

Technology

Customers

Employees

Develop New Measures of Success

Financial Success

Social Responsibility

Environment

Integrating Financial Results, Society Equity, and Sustainability

Identify What Needs to Be Done

APICS E&R Foundation Inc.

TABLE 18.4 Gaps in Implementing Global Supply Chain Integration

McKinsey Study

TABLE 18.5 Challenges for Future Supply Chains

University of Tennessee

Adapt to Government Actions

Environment

Business Ethics

Product Safety

Social Equity

Infrastructure

Capitalize on Third-Party Skills

Direct Support: Outsourcing

Indirect Support: Financing and Insurance

Advisory: Consulting and Training

Analyst: Measure Performance and Identify Needs

Manager: Virtual Holding Company

Utilize Information Technology

Enterprise Resource Planning Extension

Service-Oriented Architecture

Internet Processes

Interorganizational Systems

Take Advantage of Other Technologies

Organization and Teams

Project Management

Process Technology

Build Strategic and Operational Plans

Continue the Drive for Collaboration

Develop Performance Measures for Supply Chain Management

Integrate Delivery Effectiveness Measures

Integrate Cost and Quality Measures

Supplier Profitability

Effectiveness of Supply Chain Integration

Structure the Organization to Manage Change

Purchasing

Integrate All Functions

Educate the Work Force

Increase Marketing Influence

Overcome Inertia

Expand Knowledge Management*

From Data to Information

From Information to Knowledge

FIGURE 18.1 The knowledge corridor.

From Knowledge to Wisdom

Some Ways to Learn

Obstacles to Knowledge Transfer

Will Knowledge Replace “Things”?

Acquire Data Analytics Capabilities*

Background

Benefits

Obstacles

Applications

Techniques

Conclusions

Integrate Manufacturing and Services

Apply Chaos Theory to Business

Summary

Hot Topic

Hot Topics in the Supply Chain: How Social Media Knocked Down the Lean Finely Textured Beef Industry

BACKGROUND

TROUBLE BREWING

References

Questions for Discussion

Discussion Questions

References

Back Matter

Index

People also search for Principles of Supply Chain Management 2nd Edition :

fundamental principles of supply chain management

principles of supply chain management a balanced approach 6th edition

fundamental principles of supply chain management textbook pdf

7 principles of supply chain management pdf

principles of supply chain management a balanced approach pdf