Distillation Design and Control Using Aspen Simulation 2nd Edition by William Luyben 1118411439 9781118411438

$70.00 Original price was: $70.00.$35.00Current price is: $35.00.

Instant download Distillation Design and Control Using Aspen Simulation 2nd Edition by William L. Luyben after payment

Distillation Design and Control Using Aspen Simulation 2nd Edition by William Luyben – Ebook PDF Instant Download/Delivery: 1118411439, 9781118411438

Full dowload Distillation Design and Control Using Aspen Simulation 2nd Edition after payment

Product details:

• ISBN 10:1118411439

• ISBN 13:9781118411438

• Author:William Luyben

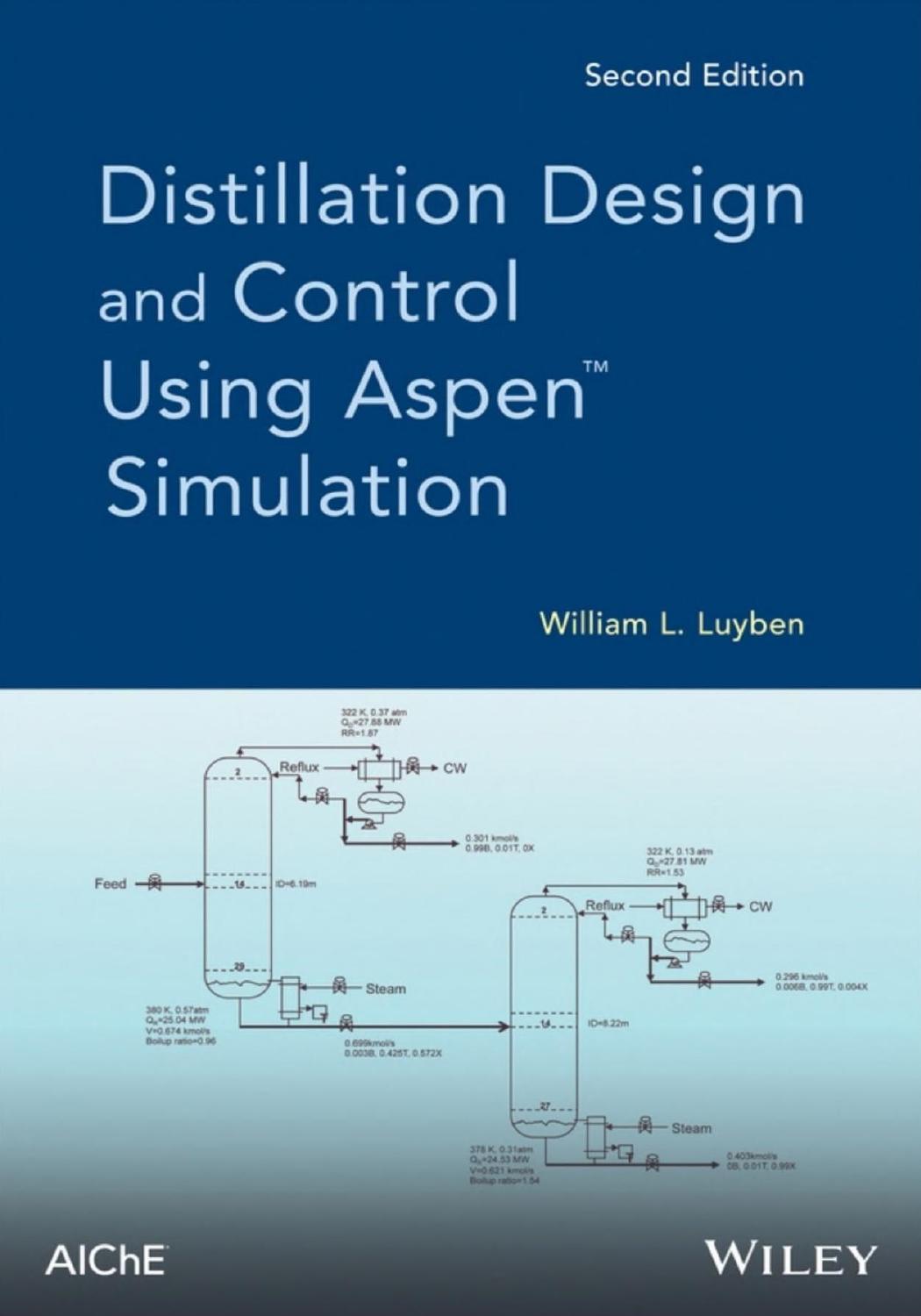

As the search for new energy sources grows ever more urgent, distillation remains at the forefront among separation methods in the chemical, petroleum, and energy industries. Most importantly, as renewable sources of energy and chemical feedstocks continue to be developed, distillation design and control will become ever more important in our ability to ensure global sustainability.

Using the commercial simulators Aspen Plus® and Aspen Dynamics®, this text enables readers to develop optimal steady-state designs for distillation systems. Moreover, readers will discover how to develop effective control structures. While traditional distillation texts focus on the steady-state economic aspects of distillation design, this text also addresses such issues as dynamic performance in the face of disturbances.

Distillation Design and Control Using Aspen Simulation 2nd Table of contents:

Chapter 1: Fundamentals of Vapor–Liquid–Equilibrium (VLE)

1.1 Vapor Pressure

1.2 Binary VLE Phase Diagrams

1.3 Physical Property Methods

1.4 Relative Volatility

1.5 Bubble Point Calculations

1.6 Ternary Diagrams

1.7 VLE Nonideality

1.8 Residue Curves for Ternary Systems

1.9 Distillation Boundaries

1.10 Conclusions

Reference

Chapter 2: Analysis of Distillation Columns

2.1 Design Degrees of Freedom

2.2 Binary Mccabe–Thiele Method

2.3 Approximate Multicomponent Methods

2.4 Conclusions

Chapter 3: Setting Up a Steady-State Simulation

3.1 Configuring a New Simulation

3.2 Specifying Chemical Components and Physical Properties

3.3 Specifying Stream Properties

3.4 Specifying Parameters of Equipment

3.5 Running the Simulation

3.6 Using Design Spec/Vary Function

3.7 Finding the Optimum Feed Tray and Minimum Conditions

3.8 Column Sizing

3.9 Conceptual Design

3.10 Conclusions

Chapter 4: Distillation Economic Optimization

4.1 Heuristic Optimization

4.2 Economic Basis

4.3 Results

4.4 Operating Optimization

4.5 Optimum Pressure for Vacuum Columns

4.6 Conclusions

Chapter 5: More Complex Distillation Systems

5.1 Extractive Distillation

5.2 Ethanol Dehydration

5.3 Pressure-Swing Azeotropic Distillation

5.4 Heat-Integrated Columns

5.5 Conclusions

Chapter 6: Steady-State Calculations for Control Structure Selection

6.1 Control Structure Alternatives

6.2 Feed Composition Sensitivity Analysis (ZSA)

6.3 Temperature Control Tray Selection

6.4 Conclusions

Reference

Chapter 7: Converting From Steady-State to Dynamic Simulation

7.1 Equipment Sizing

7.2 Exporting to Aspen Dynamics

7.3 Opening the Dynamic Simulation in Aspen Dynamics

7.4 Installing Basic Controllers

7.5 Installing Temperature and Composition Controllers

7.6 Performance Evaluation

7.7 Conclusions

Chapter 8: Control of More Complex Columns

8.1 Extractive Distillation Process

8.2 Columns with Partial Condensers

8.3 Control of Heat-Integrated Distillation Columns

8.4 Control of Azeotropic Columns/Decanter System

8.5 Unusual Control Structure

8.6 Conclusions

References

Chapter 9: Reactive Distillation

9.1 Introduction

9.2 Types of Reactive Distillation Systems

9.3 Tame Process Basics

9.4 Tame Reaction Kinetics and Vle

9.5 Plantwide Control Structure

9.6 Conclusions

References

Chapter 10: Control of Sidestream Columns

10.1 Liquid Sidestream Column

10.2 Vapor Sidestream Column

10.3 Liquid Sidestream Column with Stripper

10.4 Vapor Sidestream Column with Rectifier

10.5 Sidestream Purge Column

10.6 Conclusions

Chapter 11: Control of Petroleum Fractionators

11.1 Petroleum Fractions

11.2 Characterization Crude Oil

11.3 Steady-State Design of Preflash Column

11.4 Control of Preflash Column

11.5 Steady-State Design of Pipestill

11.6 Control of Pipestill

11.7 Conclusions

References

Chapter 12: Divided-Wall (Petlyuk) Columns

12.1 Introduction

12.2 Steady-State Design

12.3 Control of the Divided-Wall Column

12.4 Control of the Conventional Column Process

12.5 Conclusions and Discussion

References

Chapter 13: Dynamic Safety Analysis

13.1 Introduction

13.2 Safety Scenarios

13.3 Process Studied

13.4 Basic Radfrac Models

13.5 Radfrac Model with Explicit Heat-Exchanger Dynamics

13.6 Dynamic Simulations

13.7 Comparison of Dynamic Responses

13.8 Other Issues

13.9 Conclusions

Reference

Chapter 14: Carbon Dioxide Capture

14.1 Carbon Dioxide Removal in Low-Pressure Air Combustion Power Plants

14.2 Carbon Dioxide Removal in High-Pressure IGCC Power Plants

14.3 Conclusions

References

Chapter 15: Distillation Turndown

15.1 Introduction

15.2 Control Problem

15.3 Process Studied

15.4 Dynamic Performance for Ramp Disturbances

15.5 Dynamic Performance for Step Disturbances

15.6 Other Control Structures

15.7 Conclusions

References

Chapter 16: Pressure-Compensated Temperature Control in Distillation Columns

16.1 Introduction

16.2 Numerical Example Studied

16.3 Conventional Control Structure Selection

16.4 Temperature/Pressure/Composition Relationships

16.5 Implementation in Aspen Dynamics

16.6 Comparison of Dynamic Results

16.7 Conclusions

References

Chapter 17: Ethanol Dehydration

17.1 Introduction

17.2 Optimization of the Beer Still (Preconcentrator)

17.3 Optimization of the Azeotropic and Recovery Columns

17.4 Optimization of the Entire Process

17.5 Cyclohexane Entrainer

17.6 Flowsheet Recycle Convergence

17.7 Conclusions

References

Chapter 18: External Reset Feedback to Prevent Reset Windup

18.1 Introduction

18.2 External Reset Feedback Circuit Implementation

18.3 Flash Tank Example

18.4 Distillation Column Example

18.5 Conclusions

References

Index

People also search for Distillation Design and Control Using Aspen Simulation 2nd:

distillation design and control using

distillation design and control using aspen simulation pdf

what is distillation explain with diagram

how to make and store distilled water

what is distillation diagram