Introduction to Catalysis and Industrial Catalytic Processes 1st edition by Robert Farrauto, Lucas Dorazio, Bartholomew ISBN 1119101673 978-1119101673

$70.00 Original price was: $70.00.$35.00Current price is: $35.00.

Instant download Introduction to Catalysis and Industrial Catalytic Processes Robert J. Farrauto & Lucas Dorazio & C. H. Bartholomew after payment

Introduction to Catalysis and Industrial Catalytic Processes 1st edition by Robert Farrauto, Lucas Dorazio, Bartholomew – Ebook PDF Instant Download/Delivery: 1119101673 , 978-1119101673

Full download Introduction to Catalysis and Industrial Catalytic Processes 1st edition after payment

Product details:

ISBN 10: 1119101673

ISBN 13: 978-1119101673

Author: Robert Farrauto, Lucas Dorazio, Bartholomew

Introduces major catalytic processes including products from the petroleum, chemical, environmental and alternative energyindustries

- Provides an easy to read description of the fundamentals of catalysis and some of the major catalytic industrial processes used today

- Offers a rationale for process designs based on kinetics and thermodynamics

- Alternative energy topics include the hydrogen economy, fuels cells, bio catalytic (enzymes) production of ethanol fuel from corn and biodiesel from vegetable oils

- Problem sets of included with answers available to faculty who use the book

Introduction to Catalysis and Industrial Catalytic Processes 1st Table of contents:

CHAPTER 1: CATALYST FUNDAMENTALS OF INDUSTRIAL CATALYSIS

1.1 INTRODUCTION

1.2 CATALYZED VERSUS NONCATALYZED REACTIONS

1.3 PHYSICAL STRUCTURE OF A HETEROGENEOUS CATALYST

1.4 ADSORPTION AND KINETICALLY CONTROLLED MODELS FOR HETEROGENEOUS CATALYSIS

1.5 SUPPORTED CATALYSTS: DISPERSED MODEL

1.6 SELECTIVITY

CHAPTER 2: THE PREPARATION OF CATALYTIC MATERIALS

2.1 INTRODUCTION

2.2 CARRIER MATERIALS

2.3 INCORPORATING THE ACTIVE MATERIAL INTO THE CARRIER

2.4 FORMING THE FINAL SHAPE OF THE CATALYST

2.5 CATALYST PHYSICAL STRUCTURE AND ITS RELATIONSHIP TO PERFORMANCE

2.6 NOMENCLATURE FOR DISPERSED CATALYSTS

CHAPTER 3: CATALYST CHARACTERIZATION

3.1 INTRODUCTION

3.2 PHYSICAL PROPERTIES OF CATALYSTS

3.3 CHEMICAL AND PHYSICAL MORPHOLOGY STRUCTURES OF CATALYTIC MATERIALS

3.4 SPECTROSCOPY

CHAPTER 4: REACTION RATE IN CATALYTIC REACTORS

4.1 INTRODUCTION

4.2 SPACE VELOCITY, SPACE TIME, AND RESIDENCE TIME

4.3 DEfiNITION OF REACTION RATE

4.4 RATE OF SURFACE KINETICS

4.5 RATE OF BULK MASS TRANSFER

4.6 RATE OF PORE DIFFUSION

4.7 APPARENT ACTIVATION ENERGY AND THE RATE-LIMITING PROCESS

4.8 REACTOR BED PRESSURE DROP

4.9 SUMMARY

CHAPTER 5: CATALYST DEACTIVATION

5.1 INTRODUCTION

5.2 THERMALLY INDUCED DEACTIVATION

5.3 POISONING

5.4 COKE FORMATION AND CATALYST REGENERATION

CHAPTER 6: GENERATING HYDROGEN AND SYNTHESIS GAS BY CATALYTIC HYDROCARBON STEAM REFORMING

6.1 INTRODUCTION

6.2 LARGE-SCALE INDUSTRIAL PROCESS FOR HYDROGEN GENERATION

6.3 HYDROGEN GENERATION FOR FUEL CELLS

6.4 SUMMARY

CHAPTER 7: AMMONIA, METHANOL, FISCHER–TROPSCH PRODUCTION

7.1 AMMONIA SYNTHESIS

7.2 METHANOL SYNTHESIS

7.3 FISCHER–TROPSCH SYNTHESIS

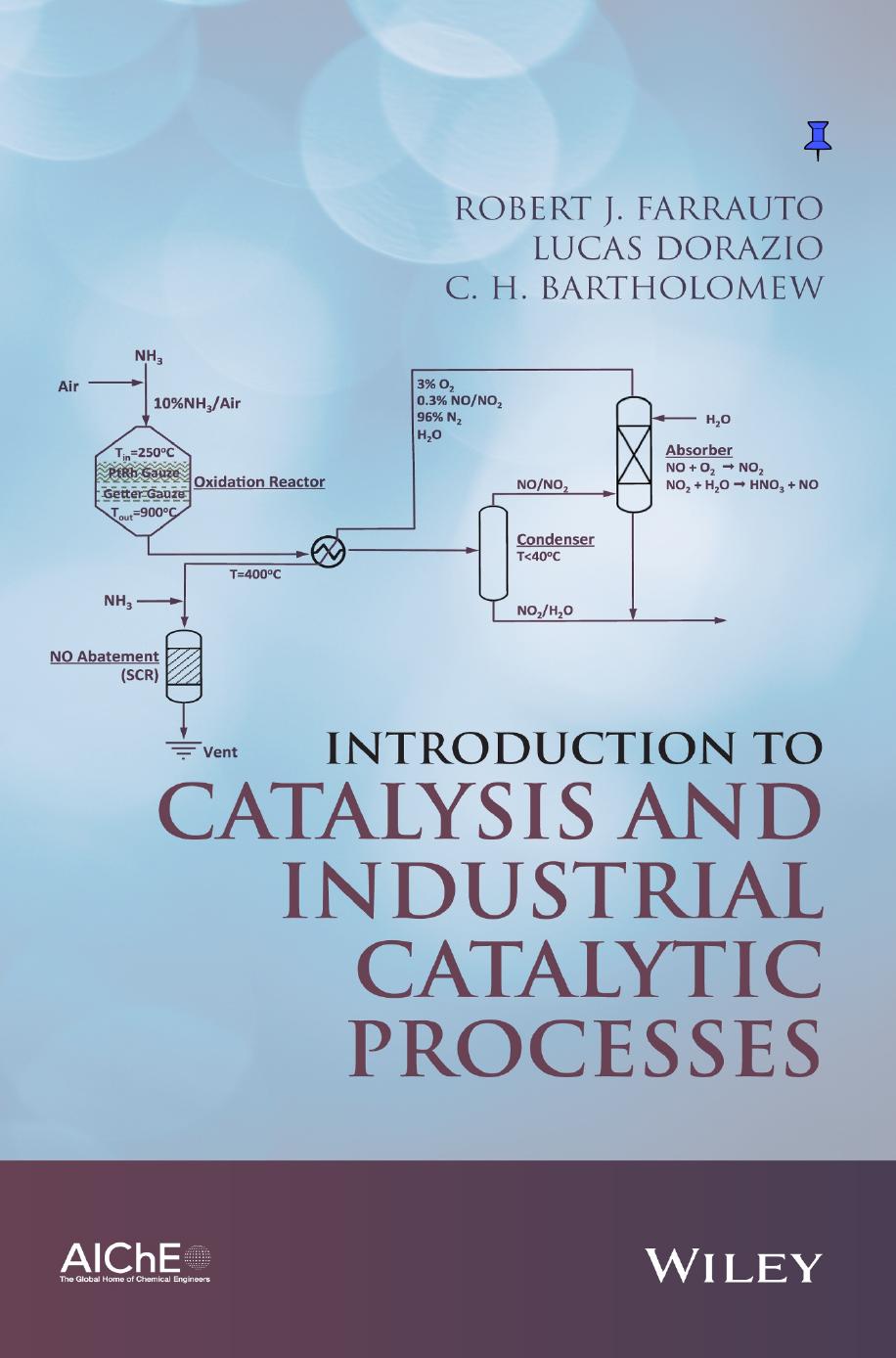

CHAPTER 8: SELECTIVE OXIDATIONS

8.1 NITRIC ACID

8.2 HYDROGEN CYANIDE

8.3 THE CLAUS PROCESS: OXIDATION OF H2S

8.4 SULFURIC ACID

8.5 ETHYLENE OXIDE

8.6 FORMALDEHYDE

8.7 ACRYLIC ACID

8.8 MALEIC ANHYDRIDE

8.9 ACRYLONITRILE

CHAPTER 9: HYDROGENATION, DEHYDROGENATION, AND ALKYLATION

9.1 INTRODUCTION

9.2 HYDROGENATION

9.3 HYDROGENATION REACTIONS AND CATALYSTS

9.4 DEHYDROGENATION

9.5 ALKYLATION

CHAPTER 10: PETROLEUM PROCESSING

10.1 CRUDE OIL

10.2 DISTILLATION

10.3 HYDRODEMETALIZATION AND HYDRODESULFURIZATION

10.4 HYDROCARBON CRACKING

10.5 NAPHTHA REFORMING

CHAPTER 11: HOMOGENEOUS CATALYSIS AND POLYMERIZATION CATALYSTS

11.1 INTRODUCTION TO HOMOGENEOUS CATALYSIS

11.2 HYDROFORMYLATION: ALDEHYDES FROM OLEfiNS

11.3 CARBOXYLATION: ACETIC ACID PRODUCTION

11.4 ENZYMATIC CATALYSIS

11.5 POLYOLEfiNS

CHAPTER 12: CATALYTIC TREATMENT FROM STATIONARY SOURCES: HC, CO, NOX, AND O3

12.1 INTRODUCTION

12.2 CATALYTIC INCINERATION OF HYDROCARBONS AND CARBON MONOXIDE

12.3 FOOD PROCESSING

12.4 NITROGEN OXIDE (NOX) REDUCTION FROM STATIONARY SOURCES

12.5 CO2 REDUCTION

CHAPTER 13: CATALYTIC ABATEMENT OF GASOLINE ENGINE EMISSIONS

13.1 EMISSIONS AND REGULATIONS

13.2 CATALYTIC REACTIONS OCCURRING DURING CATALYTIC ABATEMENT

13.3 FIRST-GENERATION CONVERTERS: OXIDATION CATALYST

13.4 THE FAILURE OF NONPRECIOUS METALS: A SUMMARY OF CATALYST HISTORY

13.5 SUPPORTING THE CATALYST IN THE EXHAUST

13.6 PREPARING THE MONOLITH CATALYST

13.7 RATE CONTROL REGIMES IN AUTOMOTIVE CATALYSTS

13.8 CATALYZED MONOLITH NOMENCLATURE

13.9 PRECIOUS METAL RECOVERY FROM CATALYTIC CONVERTERS

13.10 MONITORING CATALYTIC ACTIVITY IN A MONOLITH

13.11 THE FAILURE OF THE TRADITIONAL BEADED (PARTICULATE) CATALYSTS FOR AUTOMOTIVE APPLICATIONS

13.12 NOX, CO AND HC REDUCTION: THE THREE-WAY CATALYST

13.13 SIMULATED AGING METHODS

13.14 CLOSE-COUPLED CATALYST

13.15 FINAL COMMENTS

CHAPTER 14: DIESEL ENGINE EMISSION ABATEMENT

14.1 INTRODUCTION

14.2 CATALYTIC TECHNOLOGY FOR REDUCING EMISSIONS FROM DIESEL ENGINES

CHAPTER 15: ALTERNATIVE ENERGY SOURCES USING CATALYSIS: BIOETHANOL BY FERMENTATION, BIODIESEL BY TRANSESTERIFICATION, AND H2-BASED FUEL CELLS

15.1 INTRODUCTION: SOURCES OF NON-FOSSIL FUEL ENERGY

15.2 SOURCES OF NON-FOSSIL FUELS

15.3 FUEL CELLS

15.4 TYPES OF FUEL CELLS

15.5 THE IDEAL HYDROGEN ECONOMY

People also search for Introduction to Catalysis and Industrial Catalytic Processes 1st :

introduction to catalysis and industrial catalytic processes pdf

what is an industrial catalyst

catalyst used in catalytic cracking

industrial catalysis

introduction to enzymes and catalysis

Tags: Robert Farrauto, Lucas Dorazio, Bartholomew, Industrial Catalytic