Materials Science and Technology of Optical Fabrication 1st Edition by Tayyab Suratwala ISBN 1119423686 9781119423683

$70.00 Original price was: $70.00.$35.00Current price is: $35.00.

Instant download Materials Science and Technology of Optical Fabrication Tayyab I. Suratwala after payment

Materials Science and Technology of Optical Fabrication 1st Edition by Tayyab I. Suratwala – Ebook PDF Instant Download/Delivery: 1119423686, 978-1119423683

Full dowload Materials Science and Technology of Optical Fabrication 1st Edition after payment

Product details:

ISBN 10: 1119423686

ISBN 13: 978-1119423683

Author: Tayyab I. Suratwala

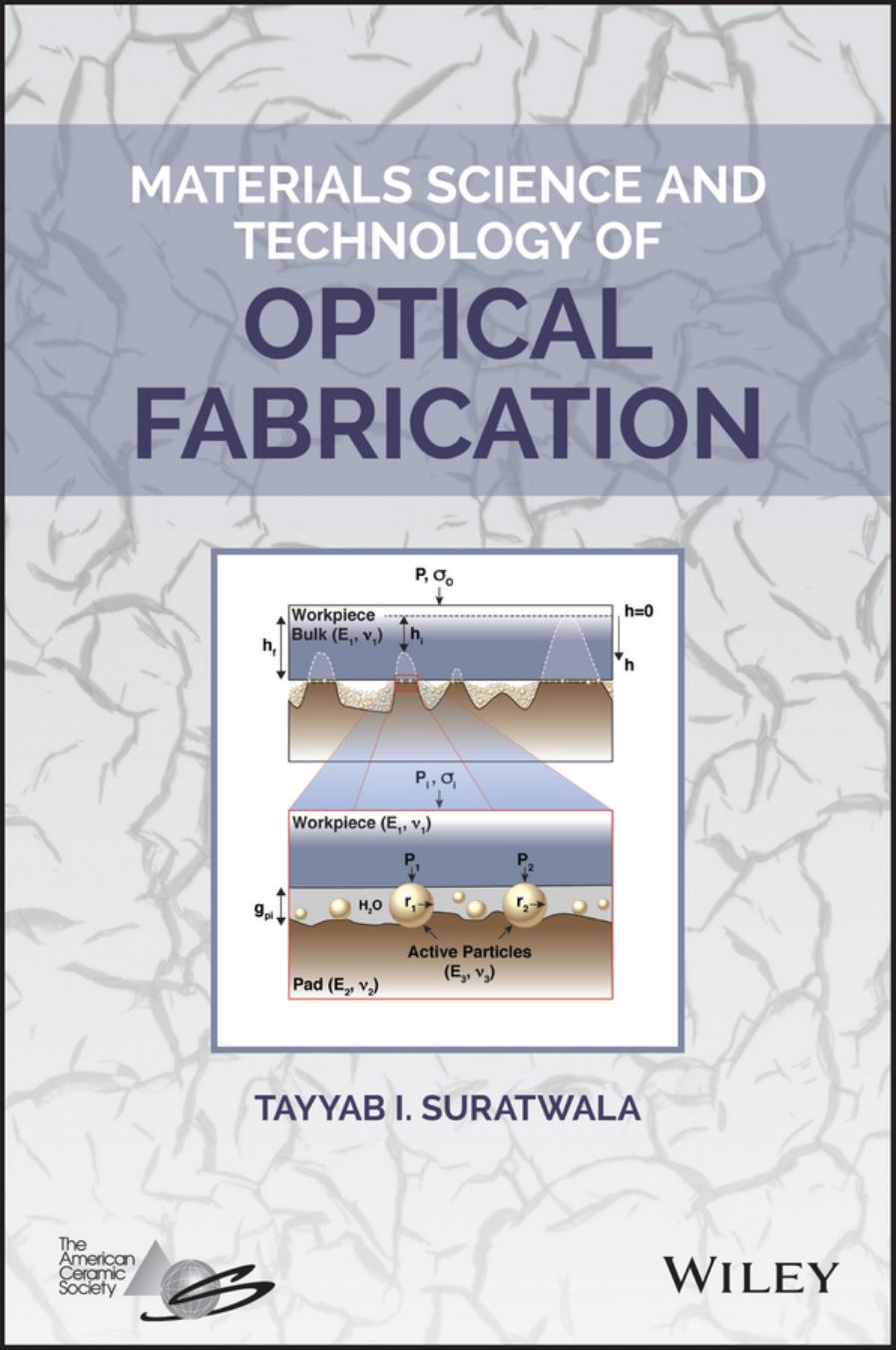

Covers the fundamental science of grinding and polishing by examining the chemical and mechanical interactions over many scale lengths

Manufacturing next generation optics has been, and will continue to be, enablers for enhancing the performance of advanced laser, imaging, and spectroscopy systems. This book reexamines the age-old field of optical fabrication from a materials-science perspective, specifically the multiple, complex interactions between the workpiece (optic), slurry, and lap. It also describes novel characterization and fabrication techniques to improve and better understand the optical fabrication process, ultimately leading to higher quality optics with higher yield.

Materials Science and Technology of Optical Fabrication is divided into two major parts. The first part describes the phenomena and corresponding process parameters affecting both the grinding and polishing processes during optical fabrication. It then relates them to the critical resulting properties of the optic (surface quality, surface figure, surface roughness, and material removal rate). The second part of the book covers a number of related topics including: developed forensic tools used to increase yield of optics with respect to surface quality (scratch/dig) and fracture loss; novel characterization and fabrication techniques used to understand/quantify the fundamental phenomena described in the first part of the book; novel and recent optical fabrication processes and their connection with the fundamental interactions; and finally, special techniques utilized to fabricate optics with high damage resistance.

- Focuses on the fundamentals of grinding and polishing, from a materials science viewpoint, by studying the chemical and mechanical interactions/phenomena over many scale lengths between the workpiece, slurry, and lap

- Explains how these phenomena affect the major characteristics of the optic workpiece―namely surface figure, surface quality, surface roughness, and material removal rate

- Describes methods to improve the major characteristics of the workpiece as well as improve process yield, such as through fractography and scratch forensics

- Covers novel characterization and fabrication techniques used to understand and quantify the fundamental phenomena of various aspects of the workpiece or fabrication process

- Details novel and recent optical fabrication processes and their connection with the fundamental interactions

Materials Science and Technology of Optical Fabrication is an excellent guidebook for process engineers, fabrication engineers, manufacturing engineers, optical scientists, and opticians in the optical fabrication industry. It will also be helpful for students studying material science and applied optics/photonics.

Materials Science and Technology of Optical Fabrication 1st Table of contents:

Part I: Fundamental Interactions – Materials Science

-

Introduction

- Optical-Fabrication Processes

- Major Characteristics of the Optical-Fabrication Process

- Material Removal Mechanisms

-

Surface Figure

- The Preston Equation

- The Preston Coefficient

- Friction at Interface

- Kinematics and Relative Velocity

- Pressure Distribution

- Applied Pressure Distribution

- Elastic Lap Response

- Hydrodynamic Forces

- Moment Forces

- Viscoelastic and Viscoplastic Lap Properties

- Viscoelastic Lap

- Viscoplastic Lap

- Workpiece–Lap Mismatch

- Workpiece Shape

- Pad Wear/Deformation

- Workpiece Bending

- Residual Grinding Stress

- Temperature

- Global Pad Properties

- Slurry Spatial Distribution

- Local Nonlinear Material Deposits

- Deterministic Surface Figure

-

Surface Quality

- Subsurface Mechanical Damage

- Indentation Fracture Mechanics

- Static Indentation

- Edge Chipping and Bevels

- Sliding Indentation

- Impact Indentation Fracture

- SSD During Grinding

- Subsurface Mechanical Depth Distributions

- Relationship of Roughness and Average Crack Length to the Maximum SSD Depth

- Fraction of Abrasive Particles Mechanically Loaded

- SSD Depth-distribution Shape

- Effect of Various Grinding Parameters on SSD Depth Distributions

- Rogue Particles During Grinding

- SSD During Polishing

- Effect of Etching on SSD

- Topographical Changes of SSD During Etching

- Influence of SSD Distribution on Etch Rate and Roughness

- Strategies to Minimize SSD

- Debris Particles and Residue

- Particles

- Residue

- Cleaning Strategies and Methods

- The Beilby Layer

- Penetration by Two-step Diffusion

- Penetration by Chemical Reactivity

- Chemical–Structural–Mechanical Model of the Beilby Layer and Polishing Process

-

Surface Roughness

- Single-Particle Removal Function

- Beilby Layer Properties

- Slurry PSD

- Pad Mechanical Properties and Topography

- Slurry Interface Interactions

- Slurry Islands and μ-roughness

- Colloidal Stability of Particles in Slurry

- Glass Reaction Product Buildup at Polishing Interface

- Three-Body Forces at Polishing Interface

- Slurry Redeposition

- Predicting Roughness

- EHMG – The Ensemble Hertzian Multi-gap Model

- Pad Deflection and Fraction of Pad Area Making Contact

- Asperity Stress, Interface Gap, Load/Particle Distribution, and Fraction of Active Particles

- Single Particle Removal Function and Load per Particle Distribution

- Monte Carlo Workpiece Roughness Simulation

- IDG Island-distribution Gap Model

- Strategies to Reduce Roughness

- Strategy 1: Reduce or Narrow the Load-per-particle Distribution

- Strategy 2: Modify the Removal Function of a Given Slurry

-

Material Removal Rate

- Grinding Material Removal Rate

- Polishing Material Removal Rate

- Deviations from Macroscopic Preston Equation

- Macroscopic Material Removal Trends from Microscopic/Molecular Phenomena

- Factors Affecting Single-particle Removal Function

- Nanoplastic Effects: Workpiece Hardness

- Chemical Effects: Condensation Rate and Partial-charge Model

Part II: Applications – Materials Technology

-

Increasing Yield: Scratch Forensics and Fractography

- Fractography 101

- Scratch Forensics

- Scratch Width

- Scratch Length

- Scratch Type

- Scratch Number Density

- Scratch Orientation and Trailing-indent Curvature

- Scratch Pattern and Curvature

- Location on Workpiece

- Scratch Forensics Example

- Slow Crack Growth and Lifetime Predictions

- Fracture Case Studies

- Temperature-induced Fracture

- Laser-Phosphate-glass Thermal Fracture

- KDP Crystal-Workpiece Thermal Fracture

- Thermal Fracture of Multilayers

- Blunt Loading with Friction

- Glass-to-metal Contact and Edge Chipping

- Glue Chipping Fracture

- Workpiece Failure from Differential Pressure

- Chemical Interactions and Surface Cracking

- Surface Cracking of Phosphate Glass

- Surface Cracking of the DKDP Crystals

-

Novel Process and Characterization Techniques

- Process Techniques

- Stiff Versus Compliant Blocking

- Strip Etch and Bulk Etch

- Pad Wear Management with Septum or Conditioner

- Hermetically Sealed, High-humidity Polishing Chamber

- Engineered Filtration System

- Slurry Chemical Stabilization

- Slurry Lifetime and Slurry Recycling

- Ultrasonic Pad Cleaning

- Workpiece Characterization Techniques

- Single-particle Removal Function Using Nanoscratching

- Subsurface Damage Measurement Using a Taper Wedge

- Stress Measurement Using the Twyman Effect

- Beilby Layer Characterization Using SIMS

- Surface Densification Using Indentation and Annealing

- Crack Initiation and Growth Constants Using Static Indentation

- Polishing- or Grinding-system Characterization Techniques

- Tail End of Slurry PSD Using SPOS

- Pad Topography Using Confocal Microscopy

- Slurry Stability Using Zeta Potential

- Temperature Distribution During Polishing Using IR Imaging

- Slurry Spatial Distribution and Viscoelastic Lap Response Using a Nonrotating Workpiece

- Slurry Reactivity Versus Distance Using Different Pad Grooves

-

Novel Polishing Methods

- Magnetorheological Finishing (MRF)

- Float Polishing

- Ion Beam Figuring (IBF)

- Convergent Polishing

- Tumble Finishing

- Other Subaperture Polishing Methods

-

Laser Damage Resistant Optics

- Laser Damage Precursors

- Reduction of SSD in Laser Optics

- Advanced Mitigation Process

People also search for Materials Science and Technology of Optical Fabrication 1st:

state three materials used for making optical fibres

what is material science and technology

materials science and technology a comprehensive treatment

applied materials optics